- Home Page

- Company Profile

-

Our Products

- Cable Drag Chain

- Duct Bellows

- Laser Machine Bellows

- Machine Covers

- Roll Up Cover

- Scissor Lift Bellows

- Telescopic Cover

- Telescopic Spring

- Way Wiper

- Cutting Services

- Laser Cutting Service

- Laser Engraving Service

- Apron Covers

- Rollway Covers

- Bellow Covers

- Round Bellow cover

- Bellow Cover

- Circular Bellow Cover

- Polygon Bellow Cover

- Way Bellow Cover

- Metal Clad Bellow Cover

- Thermic Welded Steel metal Clad bellows Cover

- Flat Bellows Cover

- C Type Industrial fabric bellows Cover

- Round Bellows Cover

- Laser machine Bellows Cover

- Square-Rectangular Bellows cover

- Milling Machine Bellows Cover

- LM Guide Rail Bellows Cover

- RUBBER BELLOWS

- High Temperature Glass / Ceramic Fabric Bellows

- Rubber Expansion Joint

- C Type Bellows

- Round / Square / Hexagonal / Octagonal Bellows

- Square Type Bellows

- Foam Bellows

- Rexene Bellows

- PVC / Plastic Coated Bellows

- Silicon Coated Fabric Bellows

- Nylon Plast Polyester Bellows

- Rubber Coated Fabric Bellows

- High Temp. Fabric Bellows

- Hexagon Bellows

- Circular Bellows

- Square Bellows

- Rectangular Bellows

- Bus Duct Bellows

- Duct Bellows

- Canvas Bellows

- Hypalon Chute Bellows

- Chute Bellows

- Hypalon Rubber Coated Nylon Fabric Bellows

- Rubber Bellow Sleeve Type

- Rubber Bellows with Caller Type

- Rubber Expansion Bellows

- Rubber Expansion Bellows

- Silicon Bellows

- Taper Bellows

- UV Resistance Fabric Bellows

- Contact Us

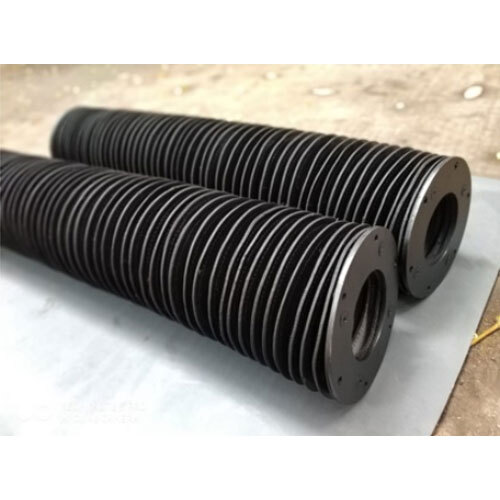

UV Resistance Fabric Bellows

1075.0 INR/Piece

Product Details:

- Surface Treatment Powder Coated

- Material

- Technique Forging

- Size Standard Sizes

- Shape Equal

- Product Type Fabric Bellows

- Color Transparent

- Click to View more

X

UV Resistance Fabric Bellows Price And Quantity

- 1075.0 INR/Piece

- 10 Piece

UV Resistance Fabric Bellows Product Specifications

- Transparent

- Forging

- Standard Sizes

- Equal

- Fabric Bellows

- Powder Coated

UV Resistance Fabric Bellows Trade Information

- 500 Piece Per Month

- 7 Days

Product Description

UV Resistance Fabric Bellows areaccordion-style, flexible protective covers made from specially coated or treated fabrics that provide excellent protection against ultraviolet (UV) radiation, dust, dirt, oil, chemicals, and moisture for machine components like guideways, shafts, and spindles.They utilize materials such asHypalonorEPDM rubber-coated nylon fabricto ensure durability, flexibility, and resistance to both UV light and other environmental hazards in industrial and machinery applications.-

A strong, flexible fabric base, often nylon or other reinforced textiles, provides the structural integrity of the bellows.

-

The fabric is coated or treated with materials like:

- Hypalon (Chlorosulfonated Polyethylene):Known for excellent UV radiation, heat, chemical, oil, and weathering resistance.

- EPDM Rubber:Highly resistant to ozone, weathering, and UV radiation, suitable for external use and hot water applications.

- Other Polymers:Materials like neoprene, polyurethane, or PVC may also offer UV resistance.

- Hypalon (Chlorosulfonated Polyethylene):Known for excellent UV radiation, heat, chemical, oil, and weathering resistance.

Robust UV Resistant Protection

Our transparent UV resistance fabric bellows provide effective shielding for sensitive equipment, especially in environments exposed to sunlight. The powder-coated surface enhances weather and chemical resistance, ensuring longevity and consistent performance in both indoor and outdoor settings.

Advanced Manufacturing Process

Each bellow is crafted using precise forging techniques, ensuring optimal structural integrity and resilience. The transparent material aids in quick inspections while maintaining the required protection, making these bellows a reliable component in industrial machinery maintenance.

FAQs of UV Resistance Fabric Bellows:

Q: How are UV resistance fabric bellows manufactured?

A: These bellows are created through advanced forging techniques, utilizing high-quality fabric with a powder-coated finish. This process ensures they possess superior strength and resistance to wear, making them suitable for rigorous industrial conditions.Q: What benefits do transparent UV resistance fabric bellows offer?

A: Transparent bellows allow for visual inspection of machinery without removing the cover, saving time in maintenance. Their UV-resistant properties extend the lifespan of both equipment and the bellows themselves.Q: When should UV resistance fabric bellows be used?

A: They are ideal for deployment in environments where equipment is exposed to sunlight, dust, or harsh chemicals, typically in industrial or manufacturing settings. Use bellows whenever you need reliable protection and easy monitoring.Q: Where can these UV resistance fabric bellows be sourced in India?

A: These bellows can be procured from exporters, manufacturers, suppliers, and service providers located throughout India, typically specializing in industrial solutions and protective components.Q: What is the usage process for UV resistance fabric bellows?

A: Installation is straightforward; the bellow is fitted over the area requiring protection, secured based on standard size and equal shape specifications, and regularly inspected thanks to its transparent design.Q: What makes the surface treatment of these bellows unique?

A: The powder-coated surface offers extra resistance to corrosion, wear, and UV degradation, significantly improving the bellows durability and functionality in demanding conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Bellow Covers' category

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese