- Home Page

- Company Profile

-

Our Products

- Cable Drag Chain

- Duct Bellows

- Laser Machine Bellows

- Machine Covers

- Roll Up Cover

- Scissor Lift Bellows

- Telescopic Cover

- Telescopic Spring

- Way Wiper

- Cutting Services

- Laser Cutting Service

- Laser Engraving Service

- Apron Covers

- Rollway Covers

- Bellow Covers

- Bellow Cover

- Round Bellow cover

- Circular Bellow Cover

- Polygon Bellow Cover

- Way Bellow Cover

- Metal Clad Bellow Cover

- Thermic Welded Steel metal Clad bellows Cover

- Flat Bellows Cover

- C Type Industrial fabric bellows Cover

- Round Bellows Cover

- Laser machine Bellows Cover

- Square-Rectangular Bellows cover

- Milling Machine Bellows Cover

- LM Guide Rail Bellows Cover

- RUBBER BELLOWS

- High Temperature Glass / Ceramic Fabric Bellows

- Rubber Expansion Joint

- C Type Bellows

- Round / Square / Hexagonal / Octagonal Bellows

- Square Type Bellows

- Foam Bellows

- Rexene Bellows

- PVC / Plastic Coated Bellows

- Silicon Coated Fabric Bellows

- Nylon Plast Polyester Bellows

- Rubber Coated Fabric Bellows

- High Temp. Fabric Bellows

- Hexagon Bellows

- Circular Bellows

- Square Bellows

- Rectangular Bellows

- Bus Duct Bellows

- Duct Bellows

- Canvas Bellows

- Hypalon Chute Bellows

- Chute Bellows

- Hypalon Rubber Coated Nylon Fabric Bellows

- Rubber Bellow Sleeve Type

- Rubber Bellows with Caller Type

- Rubber Expansion Bellows

- Rubber Expansion Bellows

- Silicon Bellows

- Taper Bellows

- UV Resistance Fabric Bellows

- Contact Us

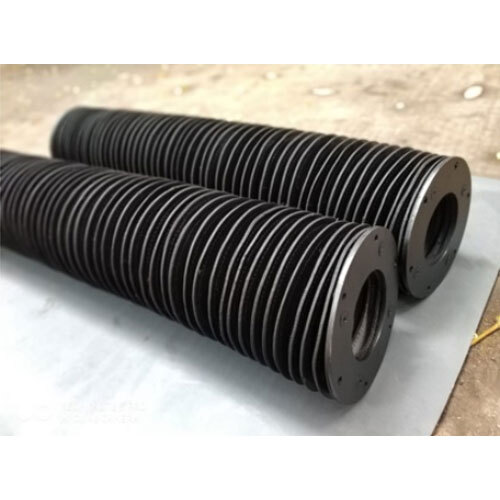

Chute Bellows

5000.0 INR/Piece

Product Details:

- Media Air/Dust

- Flange Standard Drilled Flange

- Surface Treatment Painted

- Max. Temperature up to 120C

- Material Reinforced Rubber Fabric

- Technique Casting

- Size Standard Sizes

- Click to View more

X

Chute Bellows Price And Quantity

- 5000.0 INR/Piece

- 20 Piece

Chute Bellows Product Specifications

- Painted

- Standard Drilled Flange

- up to 120C

- Cylindrical

- Casting

- Yellow

- Flange

- Air/Dust

- Reinforced Rubber Fabric

- Bellow Covers

- Bellow Covers

- Standard Sizes

- Up to 1 bar

- Round

Chute Bellows Trade Information

- 500 Piece Per Month

- 7 Days

Product Description

A chute bellows (or loading bellows/telescopic chute) isan industrial device consisting of a flexible, telescoping chute system that lowers from a conveyor or hopper to guide bulk dry powders and granules into a truck, vessel, or storage silo, minimizing dust generation during the loading process.It typically features a flexible, dust-containing outer sleeve or skirt made of durable, chemical-resistant materials and a dust collection system that can be integrated to capture fugitive dust.-

The bellows is lowered by a drive unit towards the target container, bringing the flexible discharge end close to the material pile.

-

The flexible, expandable chute material, often made of a rubber-coated fabric like PVC or Hypalon, forms a contained area for the material.

-

A suction hood or a flexible dust skirt at the bottom of the chute captures dust that is generated at the discharge point.

-

The captured dust is then conveyed via flexible piping to a dust collector and filter system, which can be an inline or separate baghouse system.

-

The telescoping action is often automated, with the chute incrementally raising as the material pile builds up, keeping the fall height to a minimum.

Customizable and Durable Design

Chute Bellows can be tailored in both shape and dimension, meeting unique application requirements with ease. The reinforced rubber fabric ensures resilience, supporting continuous operation even in harsh industrial conditions while maintaining flexibility and longevity.

Effective Sealing and Dust Protection

Specifically crafted for chute sealing and dust proofing purposes, these bellows minimize leakage and contamination. Their robust weather-resistant construction ensures consistent performance in settings where dust control and air management are critical.

Easy Installation and Maintenance

Equipped with standard drilled flanges, these bellows are simple to mount and integrate into existing systems. Their painted finish and cylindrical form not only provide a polished appearance but also facilitate straightforward cleaning and upkeep.

FAQs of Chute Bellows:

Q: How are Chute Bellows installed in industrial applications?

A: Chute Bellows are equipped with standard drilled flanges, allowing for secure and straightforward installation onto existing ductwork or chutes. Their cylindrical shape and flange design simplify the mounting process, ensuring a reliable seal and minimal maintenance requirements.Q: What are the main benefits of using reinforced rubber fabric in the construction of Chute Bellows?

A: Reinforced rubber fabric offers exceptional durability, resistance to weather and abrasion, flexibility across operating temperatures up to 120C, and longevity under rigorous working conditions. This material selection provides optimal protection and performance for dust proofing and sealing applications.Q: When should I choose a customized dimension for my Chute Bellow?

A: Custom dimensions are recommended when standard sizes do not fit your systems requirements or when unique sealing, ducting, or dust containment solutions are needed. Customization ensures a precise fit, enhanced performance, and maximum operational efficiency for your application.Q: Where are Chute Bellows commonly used in industry?

A: These bellows are typically used in sectors such as mining, cement, power plants, and bulk material handling where dust management, chute sealing, and flexible air or dust ducting are necessary to maintain a clean, safe, and efficient environment.Q: What process is used in manufacturing the Chute Bellows?

A: The Chute Bellows are produced using casting techniques, which allow for strong and consistent construction, incorporating reinforced rubber fabric and painted surfaces for enhanced durability and reliability under demanding conditions.Q: How does the weather and abrasion resistance feature benefit long-term usage?

A: Weather and abrasion resistance significantly enhance the products lifespan by safeguarding against environmental wear and physical damage. This ensures the bellows maintain their functionality, reducing replacement frequency and associated downtime in industrial operations.Q: What media can Chute Bellows safely handle?

A: Chute Bellows are specifically designed to manage air and dust media. Their resilient materials and robust construction allow them to contain these substances effectively even under working pressures up to 1 bar and at temperatures reaching 120C.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Bellow Covers' category

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese