- Home Page

- Company Profile

-

Our Products

- Cable Drag Chain

- Duct Bellows

- Laser Machine Bellows

- Machine Covers

- Roll Up Cover

- Scissor Lift Bellows

- Telescopic Cover

- Telescopic Spring

- Way Wiper

- Cutting Services

- Laser Cutting Service

- Laser Engraving Service

- Apron Covers

- Rollway Covers

- Bellow Covers

- Bellow Cover

- Round Bellow cover

- Circular Bellow Cover

- Polygon Bellow Cover

- Way Bellow Cover

- Metal Clad Bellow Cover

- Thermic Welded Steel metal Clad bellows Cover

- Flat Bellows Cover

- C Type Industrial fabric bellows Cover

- Round Bellows Cover

- Laser machine Bellows Cover

- Square-Rectangular Bellows cover

- Milling Machine Bellows Cover

- LM Guide Rail Bellows Cover

- RUBBER BELLOWS

- High Temperature Glass / Ceramic Fabric Bellows

- Rubber Expansion Joint

- C Type Bellows

- Round / Square / Hexagonal / Octagonal Bellows

- Square Type Bellows

- Foam Bellows

- Rexene Bellows

- PVC / Plastic Coated Bellows

- Silicon Coated Fabric Bellows

- Nylon Plast Polyester Bellows

- Rubber Coated Fabric Bellows

- High Temp. Fabric Bellows

- Hexagon Bellows

- Circular Bellows

- Square Bellows

- Rectangular Bellows

- Bus Duct Bellows

- Duct Bellows

- Canvas Bellows

- Hypalon Chute Bellows

- Chute Bellows

- Hypalon Rubber Coated Nylon Fabric Bellows

- Rubber Bellow Sleeve Type

- Rubber Bellows with Caller Type

- Rubber Expansion Bellows

- Rubber Expansion Bellows

- Silicon Bellows

- Taper Bellows

- UV Resistance Fabric Bellows

- Contact Us

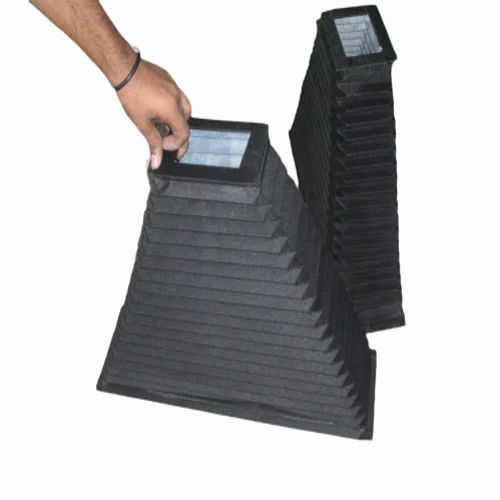

Taper Bellows

576.0 INR/Piece

Product Details:

- Surface Treatment Powder Coated

- Material Rubber

- Size Standard Sizes

- Product Type Bellow Covers

- Color Black

- Click to View more

X

Taper Bellows Price And Quantity

- 576.0 INR/Piece

- 20 Piece

Taper Bellows Product Specifications

- Bellow Covers

- Standard Sizes

- Black

- Powder Coated

- Rubber

Taper Bellows Trade Information

- 500 Piece Per Month

- 7 Days

Product Description

A taper bellows isa flexible protective cover with a conical or tapered shape, featuring one end larger than the other, that expands, compresses, and moves to accommodate motion and misalignments while sealing out contaminants like dust, oil, and moisture.Made from durable materials like rubber or fabric, tapered bellows are used in various industries for vibration isolation, sealing, and connecting components with different diameters, protecting internal parts from damage and ensuring system integrity in compact or harsh environments.-

The distinguishing feature is its shape, wider at one end and narrower at the other, allowing for a gradual transition in size and easier integration into cone-shaped mechanisms.

-

Taper bellows can expand, compress, and undergo angular movement, adapting to changing conditions and providing effective sealing.

-

They act as protective covers, shielding sensitive components from external elements such as dust, dirt, moisture, oil, chemicals, and other contaminants.

-

They can correct misalignments between connected parts in a system, ensuring proper function and reducing stress on the joints.

-

Made from materials like EPDM rubber, silicone, or PU-coated fabric, they offer high tear resistance, durability, and resistance to weather, UV, and high temperatures.

Advantages of Rubber Taper Bellows

Rubber Taper Bellows offer excellent flexibility, resistance to abrasion, and stand up well against chemicals and environmental factors. The powder-coated surface enhances their durability, making them well suited for industrial settings. Their standard sizes allow for convenient integration into various systems, providing reliable protection and extending the life of your equipment.

Applications Across Multiple Industries

Our Taper Bellows are widely used in sectors such as manufacturing, automotive, and machinery maintenance. They serve as effective barriers, safeguarding mechanical joints and components from external contaminants. By incorporating these bellows, you can ensure smoother operation and reduce maintenance costs over time, making them an essential element for efficient system management.

FAQs of Taper Bellows:

Q: How are Taper Bellows typically used in industrial applications?

A: Taper Bellows are installed to protect mechanical parts such as joints, rods, and actuators from dust, moisture, and accidental damage, enhancing operational reliability and minimizing maintenance requirements.Q: What is the process for manufacturing these rubber Taper Bellows?

A: The manufacturing process involves molding high-quality rubber into precise taper shapes using specialized tools, followed by powder coating to achieve an added layer of durability and a consistent black finish.Q: When should Taper Bellows be replaced or serviced?

A: Its recommended to inspect bellows during routine maintenance checks and replace or service them if you notice signs of wear, cracking, or loss of flexibility to prevent further damage to protected components.Q: Where are Taper Bellows commonly installed?

A: Taper Bellows are commonly installed in machinery that involves linear or rotary movement, such as hydraulic and pneumatic systems, automation equipment, and manufacturing lines.Q: What are the benefits of using powder-coated rubber Taper Bellows?

A: Powder-coated rubber Taper Bellows offer superior protection against corrosion, enhanced longevity, and resistance to harsh industrial environments, ensuring consistent performance over time.Q: Can I get Taper Bellows in different sizes and colors?

A: Our Taper Bellows come in standard sizes and a classic black color to fit most industrial applications. Customizations are available upon request to meet specific requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Bellow Covers' category

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese