- Home Page

- Company Profile

-

Our Products

- Cable Drag Chain

- Duct Bellows

- Laser Machine Bellows

- Machine Covers

- Roll Up Cover

- Scissor Lift Bellows

- Telescopic Cover

- Telescopic Spring

- Way Wiper

- Cutting Services

- Laser Cutting Service

- Laser Engraving Service

- Apron Covers

- Rollway Covers

- Bellow Covers

- Bellow Cover

- Round Bellow cover

- Circular Bellow Cover

- Polygon Bellow Cover

- Way Bellow Cover

- Metal Clad Bellow Cover

- Thermic Welded Steel metal Clad bellows Cover

- Flat Bellows Cover

- C Type Industrial fabric bellows Cover

- Round Bellows Cover

- Laser machine Bellows Cover

- Square-Rectangular Bellows cover

- Milling Machine Bellows Cover

- LM Guide Rail Bellows Cover

- RUBBER BELLOWS

- High Temperature Glass / Ceramic Fabric Bellows

- Rubber Expansion Joint

- C Type Bellows

- Round / Square / Hexagonal / Octagonal Bellows

- Square Type Bellows

- Foam Bellows

- Rexene Bellows

- PVC / Plastic Coated Bellows

- Silicon Coated Fabric Bellows

- Nylon Plast Polyester Bellows

- Rubber Coated Fabric Bellows

- High Temp. Fabric Bellows

- Hexagon Bellows

- Circular Bellows

- Square Bellows

- Rectangular Bellows

- Bus Duct Bellows

- Duct Bellows

- Canvas Bellows

- Hypalon Chute Bellows

- Chute Bellows

- Hypalon Rubber Coated Nylon Fabric Bellows

- Rubber Bellow Sleeve Type

- Rubber Bellows with Caller Type

- Rubber Expansion Bellows

- Rubber Expansion Bellows

- Silicon Bellows

- Taper Bellows

- UV Resistance Fabric Bellows

- Control Panel

- Contact Us

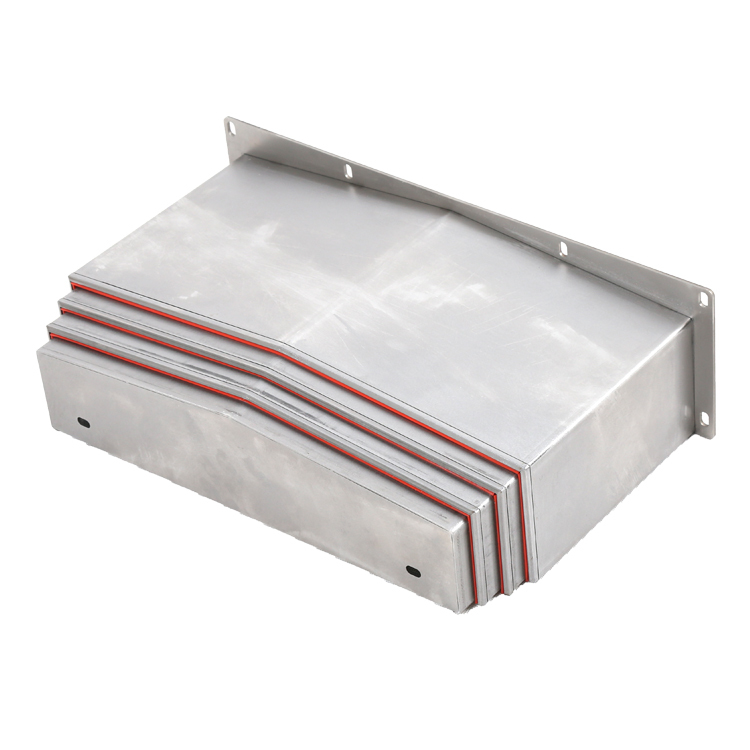

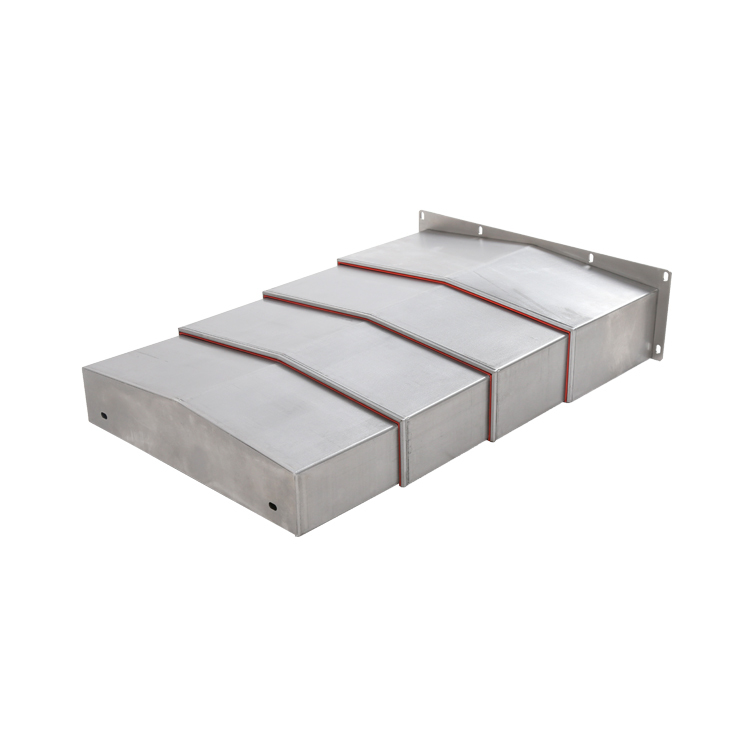

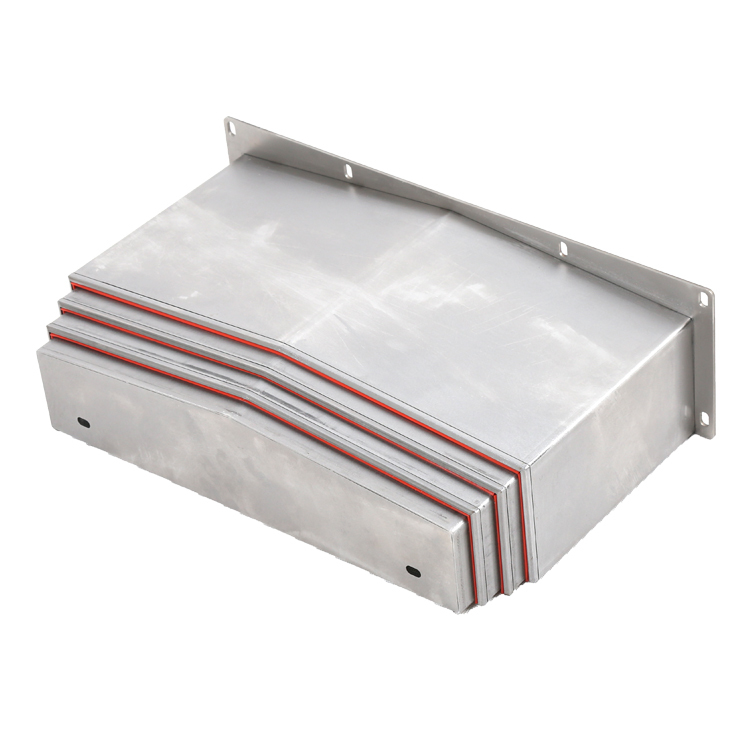

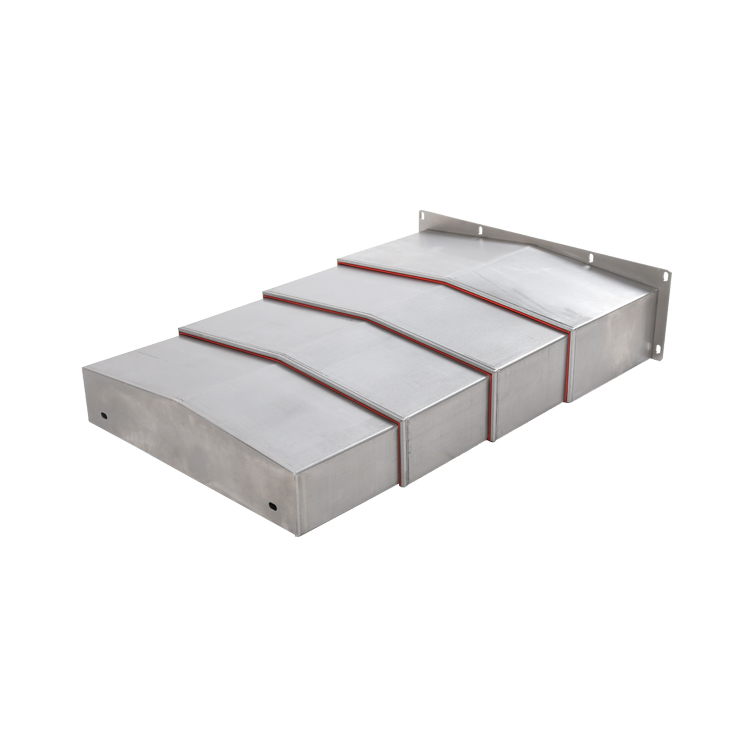

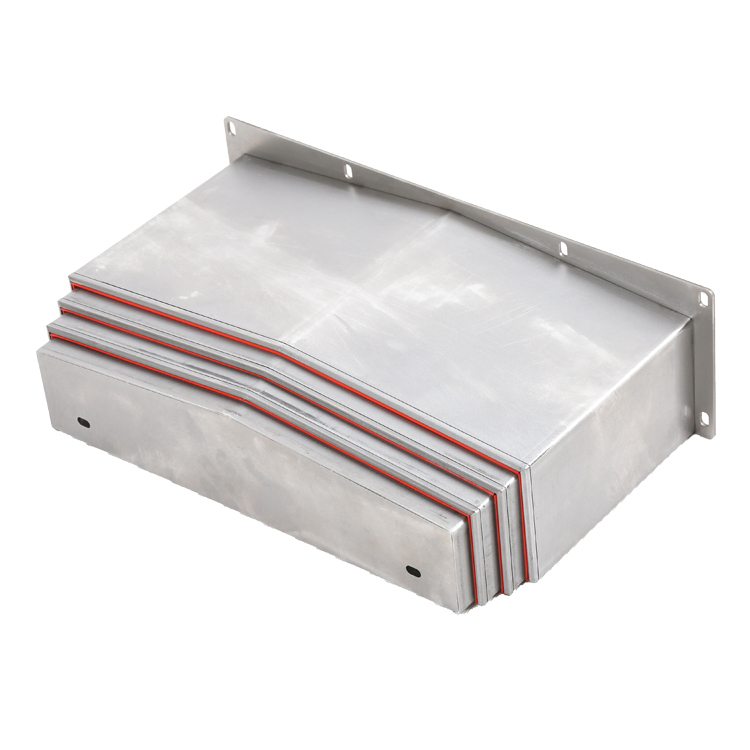

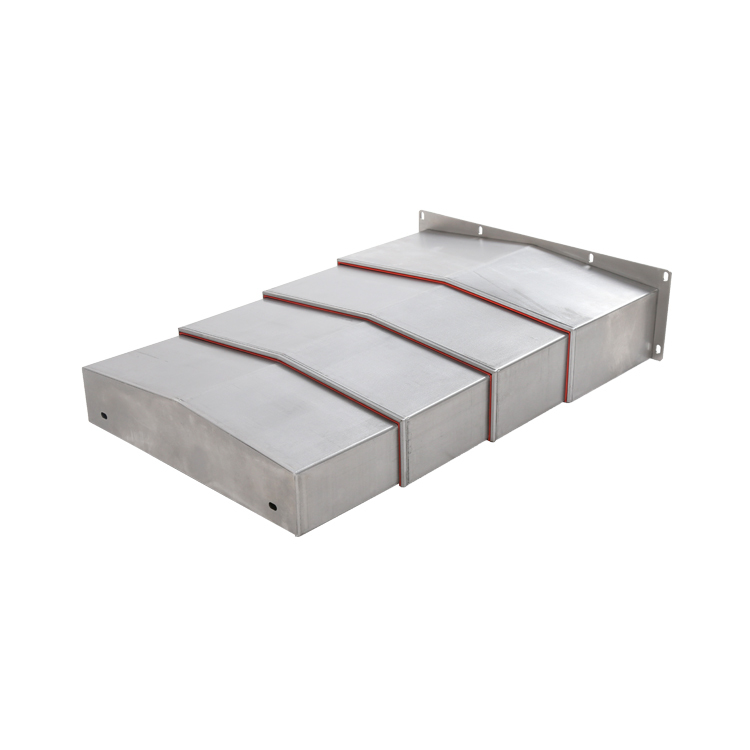

Telescopic Cover

2500 INR/Set

Product Details:

- Technology manually manufacture

- Surface Treatment zink platting

- Type sheet metal

- Material SS AND MS

- Function protection

- Application protect to machine

- Click to View more

X

Telescopic Cover Price And Quantity

- 1 Set

- 2500 INR/Set

Telescopic Cover Product Specifications

- protect to machine

- manually manufacture

- sheet metal

- SS AND MS

- zink platting

- protection

Telescopic Cover Trade Information

- pune

- 50 Set Per Month

- 1 Week

- Yes

- Free samples are available

- As per requirement

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Gujarat, Maharashtra

- ISO 9001-2015

Product Description

Telescopic Steel Covers are an important part of a machine tool to increase the runtime. The using of it makes possible perfect protection of the Guide-way, Balls-screw, etc. against mechanical influences like chips or chemical influences like coolants. Made from 1mm to 5mm thickness sheet of required material like SS,MS. Also provides good protection against accidents.Telescopic CoverFeatures: Glider Roller Lifting lugs Integral gutter Wedge dampener (catcher) Scissors Guide rails Bumper Surface-treated steel or stainless steel, also in walk-on version Wiper systems in various versions depending on the individual requirements Material-Mild Steel & Stainless Steel Applications- To protect Guide Ways of VMC,CNC & SPM Machines. It also protect LM Guide Way from Hot chips, Coolants & Foreign material. A telescopic cover protects guide-way surfaces and components of moving axis of machines.We offer: Technical design of covers within thedevelopment of new machines. Calculation of passive resistances of telescopic covers for thedesign of thedrive. Design and production of covers on thebasis of required parameters. Production of covers based on anexisting design. Measurement reports of passive resistances and vibrations of atelescopic cover. Testing of custom-made covers. Types of coversStandard coversFitted with brass sliders or rolling elements, especially with theLP8 or LP12 wiping system, characterized by low resistance and easy replacementAttenuated energy up to 12J per 1cover partLarge covers Large covers with plastic rollers for cast-iron beds. With steel bearings for hardened guides. No width or travel limitation! Reliably attenuated total cover energy 500J The typical wiping system for wiping of large areas is DV12, characterized by abig blade stroke Covers for high travel rates With sliding elements or bearing rolling elements Attenuated energy up to 25J per 1cover part Covers for grindersYou will achieve ahigh quality of ground surface with telescopes with mechanisms for tied movement of thesegments.Covers with minimum installation dimensionsWe will find asolution for tightest spaces!Cover sets, comprehensive systemsDesign of thecomplete covering system of amachine, incl. linking to themachine frame.Offered telescope material: in theDC01 designmade of stainless steelin thetelescopic cover +bellows design Working environment/TSK design Material Standard cover for dry and wet machining DC01 Cover with increased strength H360LA Cover for an abrasive environment COBRANOX Cover for a corrosive environment DIN 1.4301 Steel telescopic coversWe can custom design or reverse engineer from existing covers. They are designed to be used in environments where slide ways or screws need to be protected from heavy or hot chips and accidental damage from dropped machined components or tools.Heavy-duty front-edge wipers are fitted to all but the smallest end section to remove swarf and other debris during machine / cover movement. Each section is supported internally by brass or nylon runners or rollers, often used in combination to provide the best solution. Dampeners or buffers can be installed between each section to reduce noise and impact related wear. Control tapes or scissor actions can be fitted to aid uniform opening. Slide way wiper sealsThe service life of steel telescopic covers is usually dependent on the condition of the front-edge wipers. We stock a comprehensive range of wipers for steel telescopic covers, and we can also manufacture way wipers and linear wipers to customer specifications.The wiper seal or lip is made from hardwearing polyurethane or synthetic rubber and is vulcanized to steel or brass strip, which allows the wiper to be welded, screwed or riveted into place. The seal or lip has high resistance to abrasion, hot swarf (stainless steel can also be supplied), oils, grease and coolants. Steel telescopic cover refurbishmentMachine Covers Limited offers a complete repair, reverse engineering and fabrication service for all types of steel telescopic covers. Damaged or worn covers are reworked to a like new condition by repairing or replacing damaged sections, replacing brass side strips, replacing brass or nylon runners or rollers and replacing all front edge wipers. The reworked cover is cleaned, buffed and oiled to an original finish. We are able to produce a new replacement cover using an existing cover that is beyond economical repair as a template.Contact usfor more information about our refurbishment services. For all areas of use, in all shapes and installation positions, with or without under-gripPropertiesTelescopic Steel Covers are an important part of a machine tool to increase the runtime. The using of it makes possible: Perfectly protection of the guide way against mechanically influences like chips or chemical influences like coolants Tight fit Rustproof with stainless steel Durability In many cases possible to run over it Good protection against accidents Precise execution of first and repeat Orders because of the using of a modern CAD/CAM system and latest technologies For higher speeds, shear systems are blocked MaterialsWe use corrosion protected special plates or high-grade steel wiping and guiding elements are made of cooling resistant and are protected against abrasion. Product Details: Surface Finish Polished Temperature 40 - 100 Degree Celcius Shape Rectangular Thickness 1 to 3 mm Material Mild Steel Features Corrosion Resistance "We Are Mainly Deals In Maharastra, Gujarat"

| Material | Stainless Steel |

| Brand | SIPL |

| Surface Treatment | Powder Coated |

| Technique | Hot Rolled |

| Length | 3 Feet |

| Thickness | 1.0 to 3.0 mm |

| Width | 1-1.5 feet |

| Country of Origin | Made in India |

FAQs of Telescopic Cover:

Q: What is the function of the Telescopic Cover?

A: The function of the Telescopic Cover is to provide protection.Q: What materials are used in the Telescopic Cover?

A: The Telescopic Cover is made of stainless steel (SS) and mild steel (MS).Q: What is the type of material used in the Telescopic Cover?

A: The Telescopic Cover is manufactured using sheet metal.Q: What surface treatment is applied to the Telescopic Cover?

A: The surface treatment applied is zinc plating.Q: What is the application of the Telescopic Cover?

A: The Telescopic Cover is used to protect machines.Q: How is the Telescopic Cover manufactured?

A: The Telescopic Cover is manually manufactured.Q: Does the Telescopic Cover provide machine protection?

A: Yes, the Telescopic Cover is specifically designed to protect machines.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Telescopic Cover' category

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese