- Home Page

- Company Profile

-

Our Products

- Cable Drag Chain

- Duct Bellows

- Laser Machine Bellows

- Machine Covers

- Roll Up Cover

- Scissor Lift Bellows

- Telescopic Cover

- Telescopic Spring

- Way Wiper

- Cutting Services

- Laser Cutting Service

- Laser Engraving Service

- Apron Covers

- Rollway Covers

- Bellow Covers

- Bellow Cover

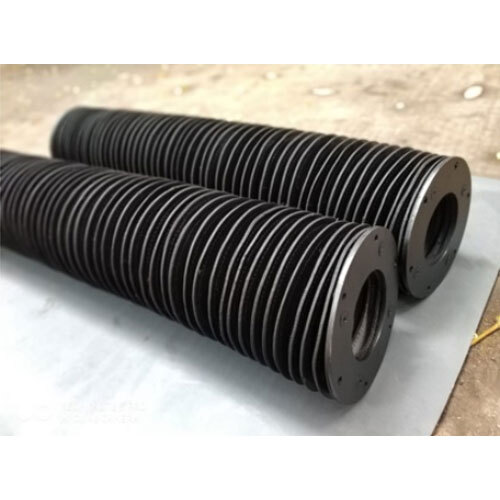

- Round Bellow cover

- Circular Bellow Cover

- Polygon Bellow Cover

- Way Bellow Cover

- Metal Clad Bellow Cover

- Thermic Welded Steel metal Clad bellows Cover

- Flat Bellows Cover

- C Type Industrial fabric bellows Cover

- Round Bellows Cover

- Laser machine Bellows Cover

- Square-Rectangular Bellows cover

- Milling Machine Bellows Cover

- LM Guide Rail Bellows Cover

- RUBBER BELLOWS

- High Temperature Glass / Ceramic Fabric Bellows

- Rubber Expansion Joint

- C Type Bellows

- Round / Square / Hexagonal / Octagonal Bellows

- Square Type Bellows

- Foam Bellows

- Rexene Bellows

- PVC / Plastic Coated Bellows

- Silicon Coated Fabric Bellows

- Nylon Plast Polyester Bellows

- Rubber Coated Fabric Bellows

- High Temp. Fabric Bellows

- Hexagon Bellows

- Circular Bellows

- Square Bellows

- Rectangular Bellows

- Bus Duct Bellows

- Duct Bellows

- Canvas Bellows

- Hypalon Chute Bellows

- Chute Bellows

- Hypalon Rubber Coated Nylon Fabric Bellows

- Rubber Bellow Sleeve Type

- Rubber Bellows with Caller Type

- Rubber Expansion Bellows

- Rubber Expansion Bellows

- Silicon Bellows

- Taper Bellows

- UV Resistance Fabric Bellows

- Contact Us

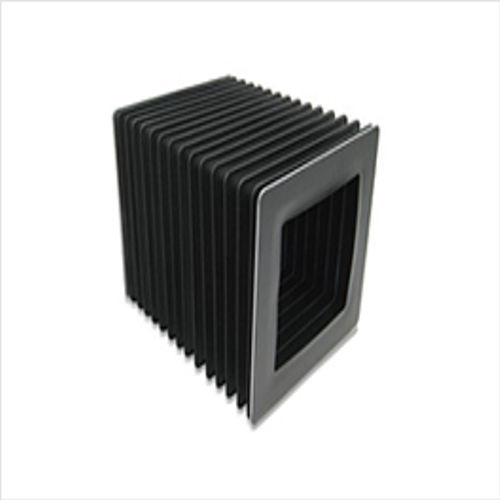

Square Bellows

440.0 INR/Piece

Product Details:

- Surface Treatment Powder Coated

- Material Rubber

- Size Standard Sizes

- Product Type Square Bellows

- Head Code Square

- Color Black

- Click to View more

X

Square Bellows Price And Quantity

- 20 Piece

- 440.0 INR/Piece

Square Bellows Product Specifications

- Standard Sizes

- Rubber

- Square Bellows

- Powder Coated

- Black

- Square

Square Bellows Trade Information

- 500 Piece Per Month

- 7 Days

Product Description

A square bellows isa flexible, hollow component with a square or rectangular cross-section, used in industrial and mechanical applications to protect components from contaminants like dust and dirt, accommodate movement, and absorb vibrations.Unlike cylindrical bellows, its square design provides a space-efficient and integrated solution for systems with square openings, and they are made from materials like rubber, fabric, or metal depending on the applications needs for durability, temperature, and chemical resistance.-

The primary purpose is to shield machinery and its components, such as ball screws, shafts, and columns, from external environmental factors like dust, dirt, moisture, high temperatures, and physical impacts.

-

Bellows are designed to expand and contract smoothly, allowing for movement and expansion in a machines components without hindering performance.

-

The square shape allows for easy integration into square or rectangular openings and connections within a mechanical system, offering a more compact and space-efficient solution compared to cylindrical bellows.

Precision-Engineered Protection

Square Bellows with standard sizes and powder-coated black finish deliver a tough barrier against dust, debris, and harsh operational conditions. Their square head design ensures compatibility with various machine profiles. Each unit, produced from premium rubber, is engineered for resilience, flexibility, and longevity in high-demand applications.

Trusted Expertise in India

As a leading exporter, manufacturer, service provider, and supplier, our company stands out in the Indian market for providing consistently high-quality machine protection solutions. We understand the critical role that bellows play in operational safety and equipment durability, ensuring each product meets the highest performance standards.

FAQs of Square Bellows:

Q: How are Square Bellows with standard sizes installed on industrial machinery?

A: Square Bellows are typically mounted over vulnerable moving parts or joints using clamps or flanges designed to fit the standard sizes. Installation is straightforward and can be performed by following the machine-specific guidelines provided by the manufacturer.Q: What are the main advantages of choosing powder-coated black rubber Square Bellows?

A: These bellows offer excellent resistance to abrasion, chemicals, and environmental factors, thanks to the robust rubber construction and powder-coated surface. The black finish not only enhances appearance but also contributes to UV resistance and extended product lifespan.Q: When should I consider replacing my machines existing bellows?

A: It is recommended to check bellows regularly for signs of cracks, wear, or loss of flexibility. Replacement is necessary if you observe any deterioration or if the bellows no longer provide a complete seal, to ensure continued protection for your equipment.Q: Where are these rubber Square Bellows commonly used?

A: Rubber Square Bellows are widely employed in industries such as manufacturing, automotive, and automation, wherever moving machine components require shielding from dust, debris, and contaminants to reduce downtime and maintenance costs.Q: What is the manufacturing process for powder-coated Square Bellows?

A: The process involves molding high-quality rubber into the square bellow shape. After initial curing, the bellows undergo a powder-coating process, where a powdered polymer is electrostatically applied and then cured under heat to create a smooth, protective black finish.Q: How do the bellows benefit industrial equipment operation?

A: By providing an effective barrier against contaminants and mechanical wear, square rubber bellows help minimize maintenance requirements, reduce the risk of equipment failure, and extend the service life of critical machine parts.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Bellow Covers' category

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese