- Home Page

- Company Profile

-

Our Products

- Cable Drag Chain

- Duct Bellows

- Laser Machine Bellows

- Machine Covers

- Roll Up Cover

- Scissor Lift Bellows

- Telescopic Cover

- Telescopic Spring

- Way Wiper

- Cutting Services

- Laser Cutting Service

- Laser Engraving Service

- Apron Covers

- Rollway Covers

- Bellow Covers

- Bellow Cover

- Round Bellow cover

- Circular Bellow Cover

- Polygon Bellow Cover

- Way Bellow Cover

- Metal Clad Bellow Cover

- Thermic Welded Steel metal Clad bellows Cover

- Flat Bellows Cover

- C Type Industrial fabric bellows Cover

- Round Bellows Cover

- Laser machine Bellows Cover

- Square-Rectangular Bellows cover

- Milling Machine Bellows Cover

- LM Guide Rail Bellows Cover

- RUBBER BELLOWS

- High Temperature Glass / Ceramic Fabric Bellows

- Rubber Expansion Joint

- C Type Bellows

- Round / Square / Hexagonal / Octagonal Bellows

- Square Type Bellows

- Foam Bellows

- Rexene Bellows

- PVC / Plastic Coated Bellows

- Silicon Coated Fabric Bellows

- Nylon Plast Polyester Bellows

- Rubber Coated Fabric Bellows

- High Temp. Fabric Bellows

- Hexagon Bellows

- Circular Bellows

- Square Bellows

- Rectangular Bellows

- Bus Duct Bellows

- Duct Bellows

- Canvas Bellows

- Hypalon Chute Bellows

- Chute Bellows

- Hypalon Rubber Coated Nylon Fabric Bellows

- Rubber Bellow Sleeve Type

- Rubber Bellows with Caller Type

- Rubber Expansion Bellows

- Rubber Expansion Bellows

- Silicon Bellows

- Taper Bellows

- UV Resistance Fabric Bellows

- Contact Us

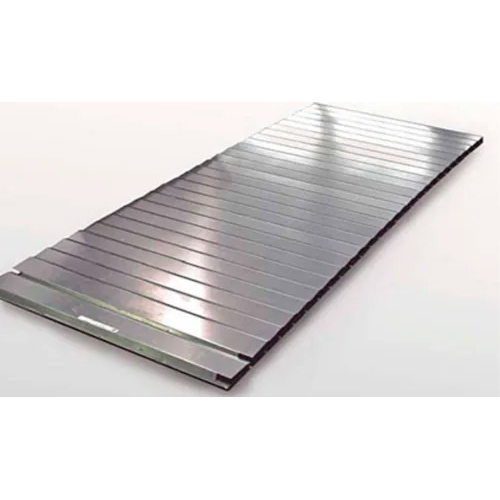

Riveted Apron Cover

5000 INR/Unit

Product Details:

- Features Durable, corrosion resistant, lightweight, easy installation

- Surface Treatment Polished

- Control System Mechanical

- Machine Type Compatible with various industrial machines

- Accuracy High precision alignment

- Technology Riveted Construction

- Accessories Type Apron cover end fittings included

- Click to View more

X

Riveted Apron Cover Price And Quantity

- 5000 INR/Unit

- 1 Unit

Riveted Apron Cover Product Specifications

- Riveted Apron Cover

- Industrial

- Durable, corrosion resistant, lightweight, easy installation

- Protection of machine guideways and moving parts

- Polished

- Mechanical

- Riveted Construction

- High precision alignment

- Compatible with various industrial machines

- Manual or Semi-Automatic

- Aluminium

- Apron Cover

- Apron cover end fittings included

- Sliver

- Industrial machinery, CNC machines, machine tools

Riveted Apron Cover Trade Information

- 30 Unit Per Month

- 1 Week

- Yes

- Free samples are available

- As Per requirement

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Maharashtra

- ISO 9001-2015

Product Description

Riveted Apron Cover

Product Details:

|

Heat Resistance |

100 Degree C |

|

Material |

Stainless Steel |

|

Color |

Silver |

|

Features |

Corrosion Resistance |

|

Usage/Application |

Splash and hose-proof |

"We Are Mainly Deals In Maharastra, Gujarat"

Exceptional Durability & Corrosion Resistance

Manufactured using high-quality aluminium and advanced riveted construction, the apron cover delivers remarkable durability and corrosion resistance for long-term industrial use. The polished finish ensures protection against rust and chemical exposure, increasing the lifespan and reliability when used in demanding environments.

Customizable For Every Application

With thickness adjustable between 0.7 and 2.0 mm and lengths tailored per machine requirements, the Riveted Apron Cover provides versatile solutions to suit various industrial applications. Its rectangular strip shape with multiple riveted sections guarantees precise fitting and high protection standards for machine guideways and moving components.

Low Maintenance & Quick Installation

Thanks to its lightweight structure and bolt-on or riveted mounting options, this apron cover is designed for quick, hassle-free installation. It requires minimal maintenance after setup, enabling operators to maximize productivity and machine safety without frequent stoppages for servicing.

FAQs of Riveted Apron Cover:

Q: How is the Riveted Apron Cover installed on industrial machines?

A: The riveted apron cover can be installed using bolt-on or riveted mounting methods, allowing secure and precise attachment to various machine types. This process is typically straightforward and requires standard mechanical fastening tools.Q: What are the benefits of using polished aluminium for this apron cover?

A: Polished aluminium provides excellent corrosion resistance, ensuring the cover remains durable even in harsh industrial environments. It also imparts a lightweight construction, which helps maintain high precision alignment and reduces strain on mechanical systems.Q: When should I consider customizing the size of the apron cover?

A: Customization is recommended whenever your machine has unique dimensions or requires specific thickness, length, or width for adequate protection. Our apron covers can be tailored to individual machine requirements to ensure optimal fit and functional efficiency.Q: Where is this type of apron cover typically used?

A: Riveted apron covers are commonly used in industrial machinery, CNC machines, and various machine tools. They serve as protective barriers for machine guideways and moving parts, reducing wear and potential damage in high-usage environments.Q: What is the maintenance process for the Riveted Apron Cover?

A: The apron cover is designed for low maintenance. Routine checks to ensure fasteners remain secure and the surface remains clean are generally sufficient. The polished aluminium finish helps minimize the need for frequent servicing.Q: How does the apron cover contribute to machine safety and performance?

A: By shielding critical guideways and moving parts from debris and physical damage, the apron cover helps maintain the machines accuracy, prolongs its service life, and reduces unscheduled downtime, enhancing overall operational safety and reliability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Apron Covers' category

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese