- Home Page

- Company Profile

-

Our Products

- Cable Drag Chain

- Duct Bellows

- Laser Machine Bellows

- Machine Covers

- Roll Up Cover

- Scissor Lift Bellows

- Telescopic Cover

- Telescopic Spring

- Way Wiper

- Cutting Services

- Laser Cutting Service

- Laser Engraving Service

- Apron Covers

- Rollway Covers

- Bellow Covers

- Bellow Cover

- Round Bellow cover

- Circular Bellow Cover

- Polygon Bellow Cover

- Way Bellow Cover

- Metal Clad Bellow Cover

- Thermic Welded Steel metal Clad bellows Cover

- Flat Bellows Cover

- C Type Industrial fabric bellows Cover

- Round Bellows Cover

- Laser machine Bellows Cover

- Square-Rectangular Bellows cover

- Milling Machine Bellows Cover

- LM Guide Rail Bellows Cover

- RUBBER BELLOWS

- High Temperature Glass / Ceramic Fabric Bellows

- Rubber Expansion Joint

- C Type Bellows

- Round / Square / Hexagonal / Octagonal Bellows

- Square Type Bellows

- Foam Bellows

- Rexene Bellows

- PVC / Plastic Coated Bellows

- Silicon Coated Fabric Bellows

- Nylon Plast Polyester Bellows

- Rubber Coated Fabric Bellows

- High Temp. Fabric Bellows

- Hexagon Bellows

- Circular Bellows

- Square Bellows

- Rectangular Bellows

- Bus Duct Bellows

- Duct Bellows

- Canvas Bellows

- Hypalon Chute Bellows

- Chute Bellows

- Hypalon Rubber Coated Nylon Fabric Bellows

- Rubber Bellow Sleeve Type

- Rubber Bellows with Caller Type

- Rubber Expansion Bellows

- Rubber Expansion Bellows

- Silicon Bellows

- Taper Bellows

- UV Resistance Fabric Bellows

- Contact Us

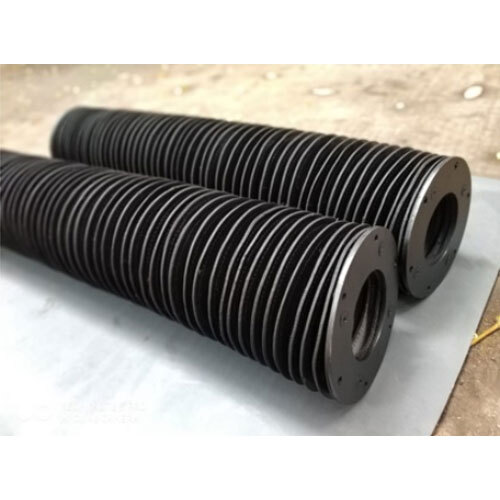

Rubber Bellows with Caller Type

1575.0 INR/Piece

Product Details:

- Surface Treatment Powder Coated

- Material Rubber

- Size Standard Sizes

- Product Type Rubber Bellows

- Color Black

- Click to View more

X

Rubber Bellows with Caller Type Price And Quantity

- 1575.0 INR/Piece

- 10 Piece

Rubber Bellows with Caller Type Product Specifications

- Rubber

- Standard Sizes

- Rubber Bellows

- Black

- Powder Coated

Rubber Bellows with Caller Type Trade Information

- 500 Piece Per Month

- 7 Days

Product Description

A "rubber bellows with collar type" isa specific design of rubber expansion joint, also known as a flexible rubber connector or compensator, that uses a circular collar for a specific method of attachment and assembly.These bellows are flexible and designed to absorb movement (axial, lateral, and angular), reduce noise and vibration, and compensate for misalignment in pipe systems.The "collar type" refers to the presence of a ring, or collar, that helps to distribute stress when the bellows are attached topipeline flangesor equipment.-

Rubber bellows consist of a number of convoluted, or ribbed, shapes that provide flexibility and the ability to deform and return to their original shape.

-

They are made from various types of rubber compounds, such as EPDM for general use and NBR (Nitrile) for oil and fuel resistance.

-

Key Features of Rubber Bellows with Caller Type

These bellows are constructed from robust rubber material, enhancing their longevity and flexibility. The powder-coated surface delivers additional protection against corrosion and abrasion, ensuring reliable performance. Offered in standard sizes, they suit various mechanical applications and are easily incorporated into systems requiring movement or vibration mitigation.

Applications and Industries Served

Rubber Bellows with Caller Type are commonly utilized in industrial plants, automotive systems, and plumbing installations. Their capacity for absorbing vibrations and thermal expansion makes them essential for machinery operating in dynamic or harsh environments. Exporters and suppliers in India ensure they are available to meet diverse industry specifications.

FAQs of Rubber Bellows with Caller Type:

Q: How are Rubber Bellows with Caller Type typically installed in mechanical systems?

A: Rubber Bellows with Caller Type are installed by attaching their caller ends to the connecting pipes or machinery flanges. Their flexible design simplifies the alignment process, and the standard sizes allow for a straightforward fit within most industrial setups.Q: What advantages does powder coating provide to these rubber bellows?

A: Powder coating adds a protective layer that improves the bellows resistance to chemicals, moisture, and abrasion. This treatment extends the products lifespan and maintains its functional integrity even in challenging industrial environments.Q: When should I use Rubber Bellows with Caller Type in my application?

A: Use Rubber Bellows with Caller Type when you need to compensate for movement, prevent leaks, reduce vibration, or protect equipment from dust and debris. They are ideal for dynamic systems requiring secure yet flexible connections.Q: Where can I find reliable exporters and suppliers of Rubber Bellows with Caller Type in India?

A: You can source these bellows from established manufacturers, exporters, and service providers across India. Many suppliers offer standard sizes and customization options to fit specific operational needs.Q: What is the manufacturing process for Rubber Bellows with Caller Type?

A: The process typically involves molding high-quality rubber into the desired shape, followed by vulcanization to enhance durability. The bellows then undergo powder coating for added surface protection before quality checks and packaging.Q: How are Rubber Bellows with Caller Type used to benefit machinery and piping systems?

A: Their flexible nature absorbs vibrations, accommodates pipe movements, and prevents misalignment issues. This protects sensitive equipment from stress, reduces maintenance costs, and improves overall system efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Bellow Covers' category

Call Me Free

Call Me Free